Soldering is a soldering technique used to join two metal surfaces. It involves the use of heat, usually from a specialized tool called an iron, and molten solder that bonds the pieces together or creates electrical connectivity between them. No matter what type of project you're working on - electronics, jewelry making, plumbing, etc. - understanding the basics of Soldering and taking time to acquire skills in Soldering can make all the difference when it comes to a successful building process! In this article, we'll look in-depth at Soldering, common solder types available in different applications, and other tips and tricks for getting started with your projects.

The Purpose of Soldering

The primary purpose of Soldering is to create reliable electrical and mechanical connections. By Soldering, you can ensure proper transmission of electrical signals, provide structural support, and prevent loose or intermittent connections. Soldering also helps protect the metal surfaces from corrosion and oxidation, extending the lifespan of the joint.

What is the process of Soldering?

The fundamentals of Soldering are straightforward. The process involves using heat to melt the solder, allowing two pieces of metal or other materials to be joined together upon cooling and hardening. For successful Soldering, the joint surfaces must be clean and free from contaminants like dirt or oil. This cleanliness facilitates a stronger bond between the metals. Flux is applied to prevent oxidation and ensure a clean, robust connection. The flux acts as a protective barrier against corrosion.

An essential factor in Soldering is the even heating of the metal. Selecting a soldering tip appropriate for the workpiece's size is vital. A too-small tip might not distribute enough heat, while a too-large tip can cause the solder to run or spill.

Temperature control plays a key role in Soldering, often employing a soldering iron with an adjustable temperature controller. The temperature should be set correctly for the specific project at hand. If the temperature is too high, there is a risk of burning or damaging the pieces being joined, whereas if it is too low, the solder will not flow properly. Achieving the right balance is essential.

Equally important is applying the solder to both surfaces being joined. Practice is vital to perfect this skill. Once the solder is melted, it should be evenly distributed across both pieces to ensure a strong bond.

Soldering can serve as a valuable method for joining two pieces of metal together, as well as an adhesive, depending on the requirements of your project. With patience and practice, Soldering can become an invaluable skill. Starting with simple projects will allow you to gradually take on more adventurous tasks.

Types of Soldering:

Soldering encompasses three primary types: Soft Soldering, Hard Soldering, and Brazing Soldering.

Soft Soldering:

Soft Soldering suits temperatures between 90 °C and 450 °C. This method employs solder materials with low melting points, often lead-based alloys. Soft Soldering is commonly used when minimal structural strength is required, particularly for joining materials with different thermal expansion properties.

Hard Soldering:

Hard Soldering is employed when temperatures surpass 450 °C. Brass and silver are frequently hard soldered, utilizing a flame or blowtorch to melt the filler metal. This type of Soldering offers enhanced mechanical strength, making it well-suited for applications demanding higher load-bearing capacities.

Brazing Soldering:

Brazing Soldering is employed when temperatures exceed 450 °C. Unlike Soldering, brazing involves a filler metal with a higher melting point than the base metal, resulting in stronger mechanical bonds between two solid metals. While brazing can be accomplished using solder, it often requires a torch or furnace to achieve the higher temperatures needed. Brazing finds extensive use in applications requiring robust and durable connections, such as plumbing, electrical wiring, and aircraft components. Furthermore, brazing allows for joining dissimilar metals, including copper and stainless steel.

Tools You Need for Soldering:

Solder:

This is the metal wire used to join two separate components. It typically comes in spools or pre-cut pieces, and its composition depends on the intended application.

Soldering Iron:

The soldering iron is the tool that heats the solder to melt and join components. It usually has an adjustable temperature control to allow you to work with different types of solder.

Soldering Wick:

This specially designed copper braid helps remove excess solder from components. It is generally used with the soldering iron to ensure proper connections.

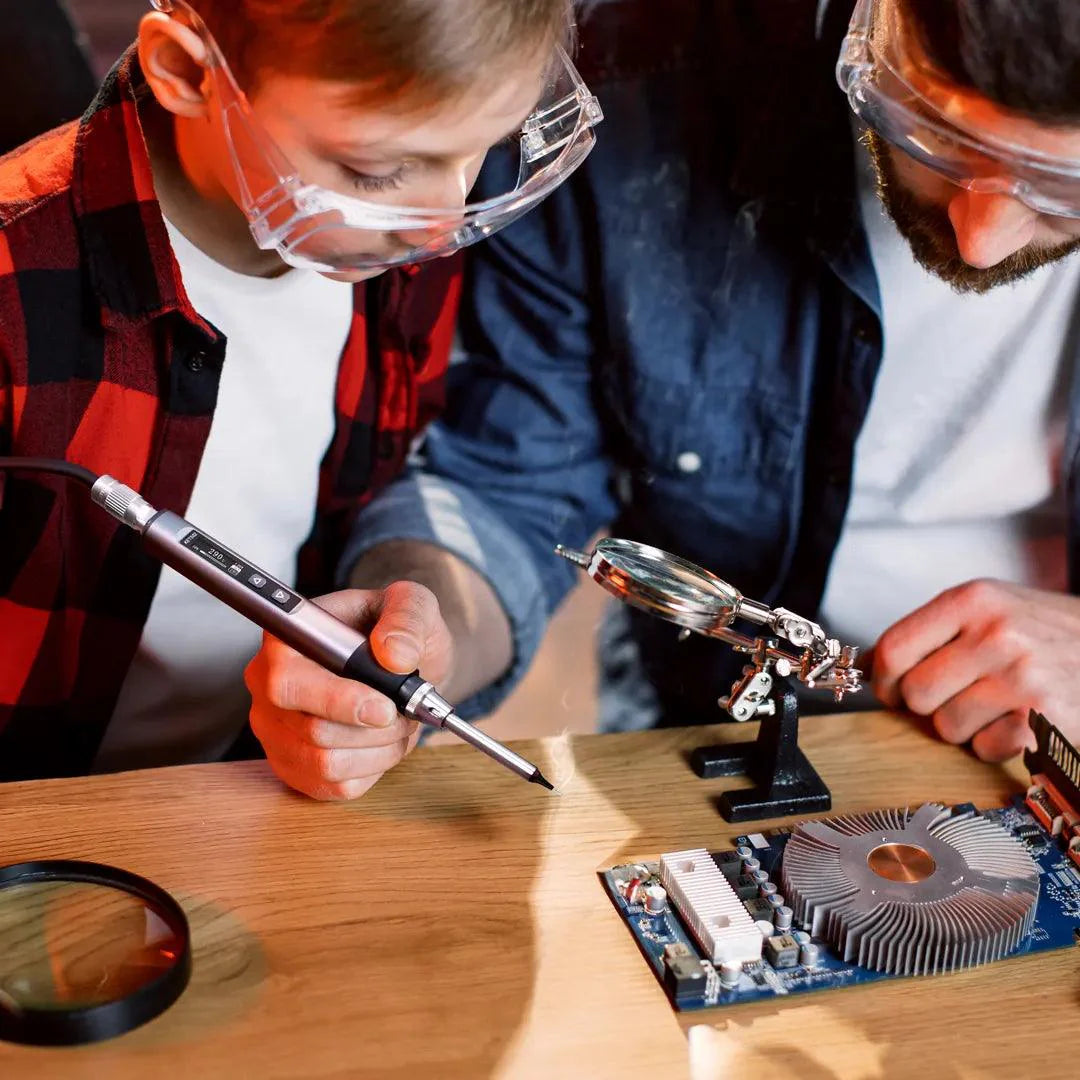

Magnifying Glass:

A magnifying glass can inspect your work when soldering, ensuring accurate placement and connection of components. It also helps you to check for any imperfections in the solder joints.

Safety precautions when soldering

- Wear heat-resistant gloves to protect your hands.

- Stand away from the element when soldering and avoid any flammable objects nearby.

- Use tweezers or clamps to hold wires that need to be heated instead of handling them with bare hands.

- Keep the cleaning sponge wet to clean the soldering iron tip.

- Turn off the soldering iron and unplug it from the outlet when you finish your work. Never leave the soldering iron unattended on a workbench. Always store it in its stand.

- Be aware of proper ventilation while working with soldered materials, as fumes can be toxic if inhaled.

- Always inspect the soldering iron before use to ensure it works properly and has no visible damage. This will help you avoid potential hazards when soldering.

- Never leave the soldering iron plugged in for more than necessary, as this could cause a fire hazard. Also, be sure to unplug the soldering iron after every use.

- Make sure to be mindful of your surroundings while working with soldered materials and be aware of any potential hazards that may arise.

-

Be aware of the soldering iron tip's temperature, typically around 400°C (752°F). Taking proper safety precautions can help you avoid injury caused by the extreme heat.

Frequently Asked Questions:

Is soldering suitable for all metals?

Soldering is primarily used for joining metals with low melting points, such as copper, tin, silver, and their alloys. It is unsuitable for all metals, especially those with high melting points like steel or cast iron.

Are there safety precautions for Soldering?

Yes, safety precautions should be followed when soldering. This includes wearing safety glasses to protect the eyes, ensuring proper ventilation to avoid inhaling fumes and handling the hot soldering iron with care to prevent burns.

Can Soldering be done on delicate electronic components?

Soldering can be done on delicate electronic components using appropriate techniques and tools. Low-temperature soldering irons, fine soldering tips, and precision control can help minimize the risk of damaging sensitive electronic parts.

Conclusion:

In conclusion, Soldering is vital for strong and reliable metal component joining. By heating and applying solder to joints, a solid bond is achieved. With diverse applications in electronics, plumbing, and jewelry making, understanding the purpose, process, and various soldering methods empowers individuals to choose the most suitable approach. Equipping oneself with the necessary tools, following safety precautions, and employing protective gear and proper ventilation ensure efficient and secure soldering work. Frequently asked questions enhance knowledge and comprehension of Soldering. Soldering is a versatile technique with endless practical possibilities for professionals and hobbyists alike to create connections, repair components, and intricate craft designs.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.